Which Technology is the Most Cost-Effective for Generating Electricity?

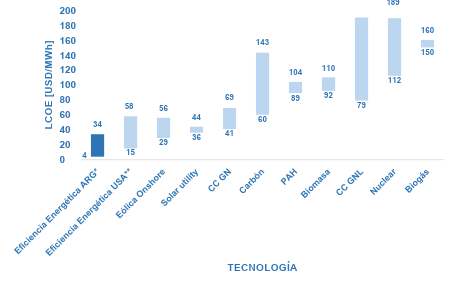

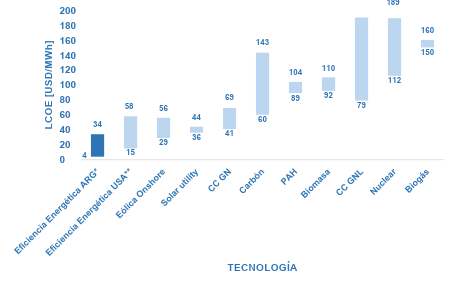

To compare the different available alternatives, the concept of Levelized Cost of Electricity (LCOE) is used, which includes all costs associated throughout the facility’s lifetime: initial investment, operation, and maintenance.

It should be clarified that this indicator does not consider aspects such as intermittency, proximity to consumption, or operational flexibility, but only the equivalent economic cost of generating 1 MWh.

Which Technologies Have the Lowest LCOE?

The latest ACEEE analysis presents the LCOE of various electricity generation technologies worldwide. Within this comparison, it is interesting to note that both wind energy and photovoltaic solar power are more competitive than many non-renewable sources, even outperforming traditional natural gas combined cycles (considering natural gas at 4 USD/MMBTU) and coal-fired steam turbine plants, which are widely used globally.

However, there is an even more competitive alternative: Energy Efficiency (EE).

The Cheapest Energy is the One That Isn’t Consumed

Based on our experience analyzing over 1,000 energy opportunities, it has been proven that the cheapest energy is the energy not consumed. It is more cost-effective to invest in energy savings than in generation, regardless of the technology used.

In terms of LCOE, energy efficiency ranges from 4 to 34 USD/MWh, placing it below any available electricity generation technology.

How is Energy Efficiency Applied in Industry?

Energy efficiency encompasses a variety of technologies, practices, and management measures tailored to each production process. Opportunities can be grouped into different categories based on investment and return:

Operational Practices and Continuous Improvement Groups (CIGs)

These represent opportunities with very low or no investment and very high profitability. Although individual savings may be smaller, the low associated cost allows achieving LCOEs as low as 4 USD/MWh, with paybacks under 12 months.

Highlights within this group include:

Simple operational practices

Consumption monitoring

Control and automation systems

These opportunities are often overlooked due to lack of information but should be the first addressed through an Energy Audit or by implementing an Energy Management System (EnMS).

Best Available Practices (BAP) and Best Available Technologies (BAT)

These involve investments in energy-efficient technologies with significant savings and average paybacks of 24 months.

Key examples include:

Installation of Variable Frequency Drives (VFDs)

Improvements in electromechanical equipment and thermal processes

Waste heat recovery

These opportunities require prior engineering studies and are categorized as energy investment projects.